The majority of humanity’s electricity comes from heat – burning coal or natural gas, nuclear fission, concentrating solar – that’s used to boil water and spin steam turbines. This method of power generation has been around since Charles Parsons first hooked a steam turbine up to a dynamo in 1884, and licensed the patent to George Westinghouse. Over the last century and a half, it’s become ubiquitous all over the world as a mature and well-optimized technology with known strengths and limitations.

One of those limitations is efficiency. While some turbines have managed to convert up to 60 percent of a heat source’s energy into electricity, the average turbine operates at closer to 35 percent efficiency. Another limitation is heat – the moving parts in turbines prevent them from operating, for example, at temperatures over 2,000 °C (3,600 °F).

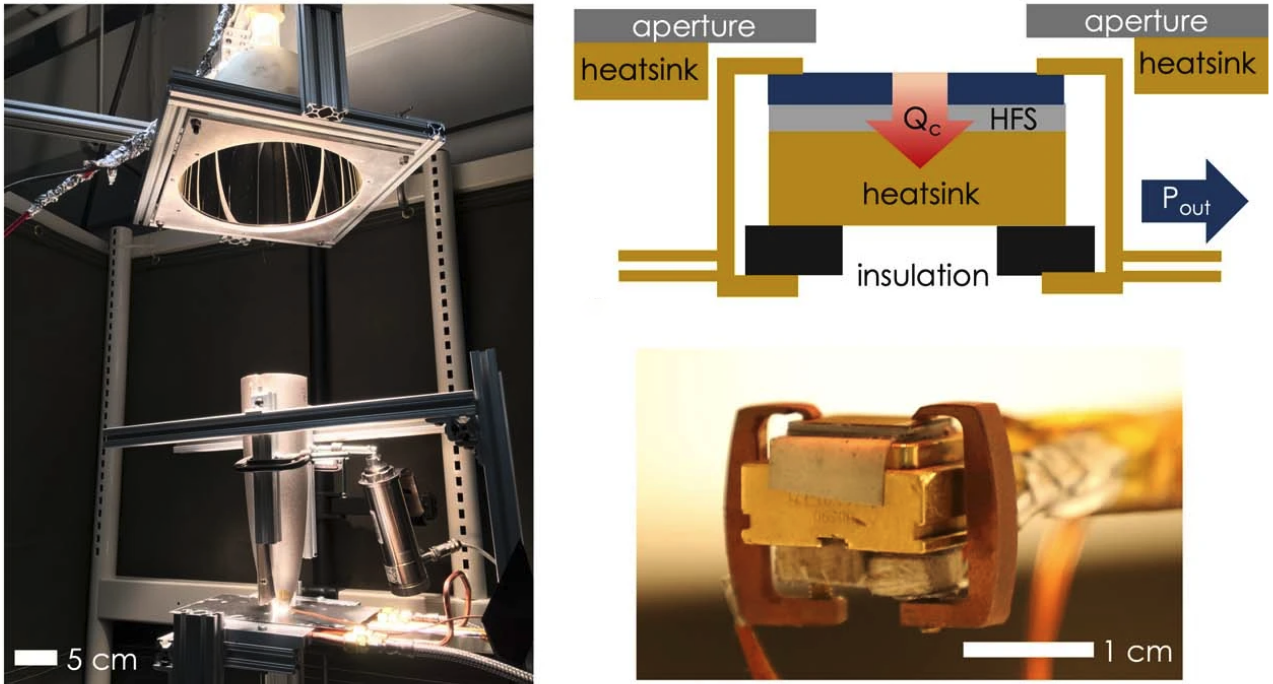

These figures come from an MIT research team that’s been working on an alternative: a heat engine with no moving parts, a thermophotovoltaic (TPV) device that the team has now demonstrated in a small 1 x 1-cm (0.4 x 0.4-in) prototype, maintaining an efficiency over 40 percent across a temperature range between 1,900 – 2,400 °C (3,450 – 4,300 °F).

That’s a significant advance, says the team, from typical TPV heat engines, most of which operate at about 20-percent efficiency, with the previous record being 32 percent, and offers a more effective way of harvesting energy than turbines under the right circumstances.

Thermophotovoltaic heat engines boil down to something like this: heat arrives and is collected by an absorber/emitter material, which takes in the heat and kicks out photons on the other side. These photons are harvested by a regular photovoltaic cell in close proximity, which converts them into usable electricity.

The MIT team made its impressive efficiency advance by tweaking a few variables. Firstly, the input heat temperature – this device is designed specifically to work at hot temperatures above the range where turbines can no longer function. This allows the team to use higher-bandgap absorber/emitter materials, which take in more energy and release higher-energy infrared photons on the emitter side – as well as photovoltaic cells designed to take maximum advantage of those high-energy photons.

Then, the team layered the photovoltaic cells – the first layer being designed to harvest the highest-energy photons at transmission-efficient higher voltages, and the second layer being there to mop up lower-energy photons. Photons that make it through both layers are reflected back onto the absorber/emitter with a mirror, so that any photons outside the optimal ranges can feed back into the start of the process and help to keep the emitter temperature up.

MIT

In a paper published in Nature, the research team discussed its record-breaking experimental results, noting that “reaching 40 percent efficiency with TPVs is notable from the standpoint that it now renders TPV as a heat engine technology that can compete with turbines. An efficiency of 40 percent is already greater than the average turbine-based heat engine efficiency in the United States, but what could make TPVs even more attractive than a turbine is the potential for lower cost, faster response times, lower maintenance, ease of integration with external heat sources and fuel flexibility.”

This novel heat engine technology operates in a temperature range that’s “applicable for natural gas or hydrogen combustion,” raising the prospect of next-generation low-emission power plants capable of extracting more power, more cheaply, from a combustion source. In the case of green hydrogen, such a plant could be free from carbon emissions, if not nitrous oxides.

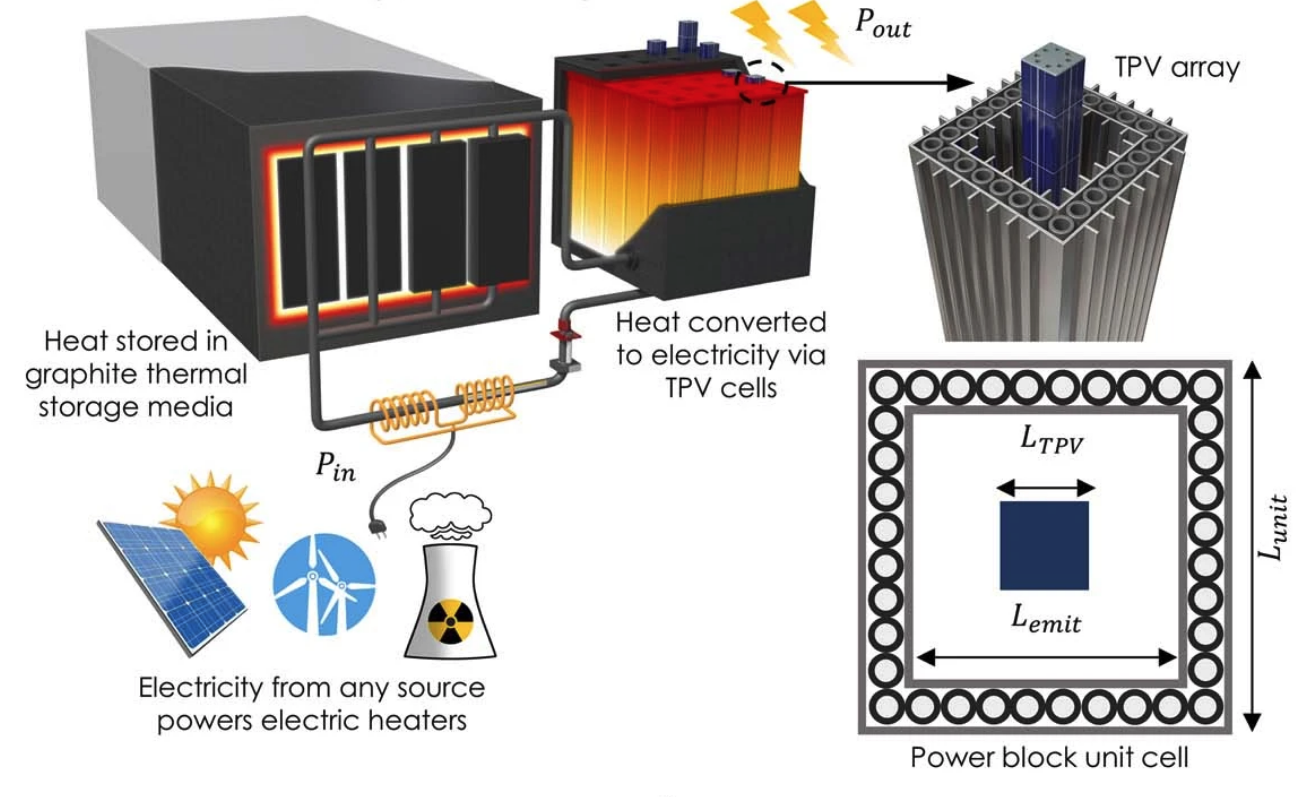

But the research team also points out that at this level of efficiency, these TPV heat engines can instantly make thermal energy grid storage (TEGS) projects an economically viable way to store and release renewable energy at the grid scale. The team’s proposed design would use excess electricity to heat up “heavily insulated banks of hot graphite,” which would act as an energy storage medium. When that energy is needed, large banks of TPV heat engines would convert it back into electricity for the grid.

The team calculates that this heat battery would operate at a round-trip efficiency somewhere around 40-55 percent. That’s somewhat wasteful compared with lithium batteries, which the team estimates operate at closer to 70 percent efficiency. But the researchers believe it’ll be so much cheaper – with a capital cost per unit energy projected at just one-tenth that of lithium batteries – that TEGS will compete favorably wherever the TPV heat engine can perform over about 35-percent efficiency.

MIT

“Thermophotovoltaic cells were the last key step toward demonstrating that thermal batteries are a viable concept,” says Asegun Henry, the Robert N. Noyce Career Development Professor in MIT’s Department of Mechanical Engineering. “This is an absolutely critical step on the path to proliferate renewable energy and get to a fully decarbonized grid … The technology is safe, environmentally benign in its life cycle, and can have a tremendous impact on abating carbon dioxide emissions from electricity production.”

What’s more, this team’s record efficiency figure will surely soon be eclipsed.

“Turbine costs and performance have already reached full maturity,” reads the study, “so there are limited prospects for future improvement, as they are at the end of their development curve. TPVs, on the other hand, are very early in their progress down a fundamentally different development curve. Consequently, TPVs have numerous prospects for both improved efficiency (for example, by improving reflectivity and lowering series resistance) and lowering cost (for example, by reusing substrates and cheaper feedstocks).”

This kind of step-change in efficiency could indeed have an enormous butterfly effect moving forward in the race to zero carbon emissions. We hope to hear a lot more about these solid-state heat engines in the next few years.

The paper is open access at the journal Nature.

Source: MIT

Source of Article