It’s certainly handy to know how fast gears or wheels are spinning, but equipping them with external sensors can be awkward and may affect their performance. That’s why scientists have devised a method of 3D-printing wireless sensors right into the things.

Named MechSense, the system was developed at MIT by a team led by mechanical engineering graduate student Marwa AlAlawi.

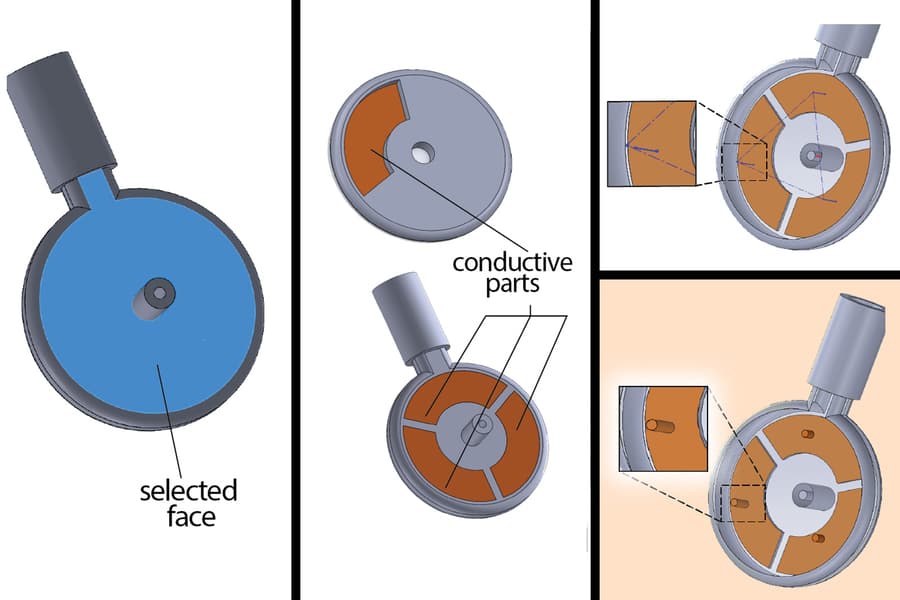

It incorporates a custom extension to the SolidWorks computer-aided design program. Utilizing that augmented software, users start by specifying the rotating and stationary parts of the mechanism they plan on printing, along with its center of rotation.

The program responds by determining the location of four patches of conductive material. One of those patches gets printed directly into the rotating part (such as a gear), which is otherwise printed out of nonconductive material. The other three patches get printed in a circle on the stationary flat surface directly below that part. Those three are separated from one another by small gaps of nonconductive material.

As the gear rotates, its wireless patch (known as a floating capacitor) repeatedly passes over the three stationary patches in sequence. Each one of them detects the resulting change in its own electrical capacitance, and relays that data to a processor via wiring in the stationary part of the mechanism. Special software in that processor is in turn able to calculate the gear’s angular position, direction of rotation and rotational speed.

MIT

In a test of the technology, the scientists created a desk lamp that changes color or brightness when its base or middle gets twisted; a planetary gearbox in which revolutions are detected and measured; plus a wheel which measures the distance that it is rolled. AlAlawi hopes that MechSense could ultimately make the field of electronics more efficient and eco-friendly.

“In an effort to generate electronic devices with very little e-waste, we want devices with smaller footprints that can still perform well,” she said. “If we take our same approach and perhaps use a different material or manufacturing process, I think we can scale down while accumulating less error using the same geometry.”

Source: MIT

Source of Article