Concrete is pretty useful, which is why it’s the most widely used construction material in the world. But it could be argued that it doesn’t really do anything. Now, engineers have made concrete that can conduct electricity and produce heat, by mixing in nanocarbon black.

Normally, concrete is an insulator against electricity, but recent research has focused on making it conductive. Adding some form of carbon to the mix usually does the trick, with past versions being tested in airport runways that automatically melt snow.

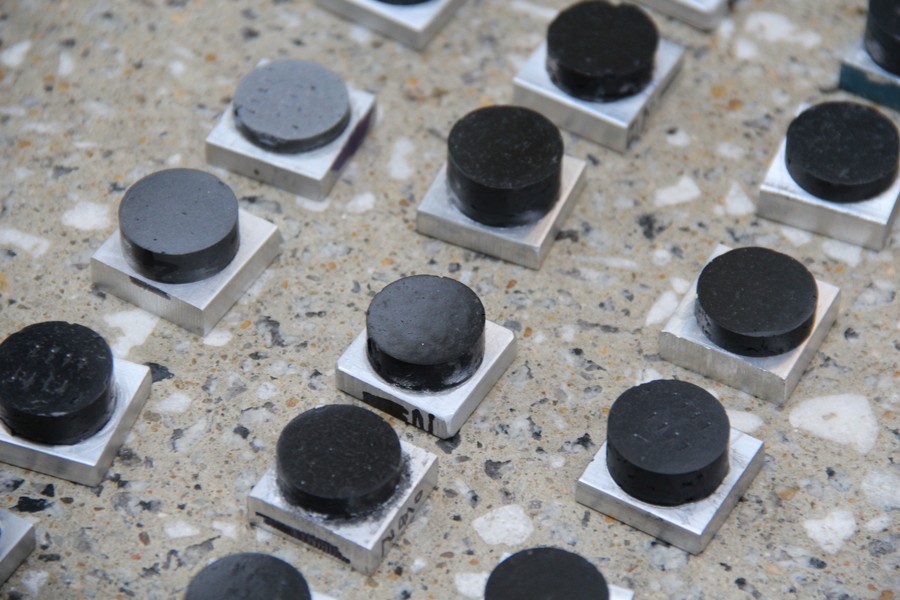

For the new study, researchers at MIT’s Concrete Sustainability Hub (CSHub) and the French National Center for Scientific Research (CNRS) added nanocarbon black, which is a cheap carbon material that boasts excellent conductivity, to concrete. At just a four-percent volume, the concrete was able to carry an electrical current – and as a result, it gave off heat too.

“Joule heating (or resistive heating) is caused by interactions between the moving electrons and atoms in the conductor,” says Nicolas Chanut, co-author of the study. “The accelerated electrons in the electric field exchange kinetic energy each time they collide with an atom, inducing vibration of the atoms in the lattice, which manifests as heat and a rise of temperature in the material.”

Andrew Logan

In tests, the team found that the nanocarbon black concrete was extremely effective at producing this heat. A voltage as small as five volts was enough to boost the surface temperature of the concrete samples to about 41 °C (106 °F). This could not only find use for de-icing surfaces outdoors, as other conductive concretes have, but the team says the material could make its way indoors too.

“This technology could be ideal for radiant indoor floor heating,” says Chanut. “Usually, indoor radiant heating is done by circulating heated water in pipes that run below the floor. But this system can be challenging to construct and maintain. When the cement itself becomes a heating element, however, the heating system becomes simpler to install and more reliable. Additionally, the cement offers more homogenous heat distribution due to the very good dispersion of the nanoparticles in the material.”

The research was published in the journal Physical Review Materials.

Source: MIT

Source of Article