The global biopharmaceutical market is predicted to grow from $478 billion in 2023 to reach $705 billion by 2028 at a compound annual growth rate of 8.07% [1]. To effectively meet this rise in demand, successful navigation of complex manufacturing processes is essential.

Throughout biopharmaceutical manufacture, materials are continuously stored, transferred and processed. With common operations including buffer or media preparation and chromatography slurry mixing, the handling of both liquids and powders is required throughout.

When handling either liquid or powder materials, measures are put in place to assure the safety of the operator and the patient, as defined by the good manufacturing practice (GMP) guidelines. Effectively meeting these regulatory requirements while assuring production efficiency can be challenging, but by harnessing innovative equipment, efficient and safe production lines can be built.

Overcoming liquid handling challenges

The use of harsh and reactive liquids — such as solvents, acids and alkalis — is often necessary, but efficient and safe handling and transfer of these liquids pose a significant challenge to biopharmaceutical manufacturers. Careful consideration must be given to ensure:

- Operator safety: The handling of harsh liquids requires robust containment protocols to safeguard personnel. If the materials used are incompatible with the liquids processed, then the containment vessel may weaken over time, increasing the risk of containment breaches. Failure to assure optimum containment at all times could harm operators, resulting in legal proceedings as regulations were not followed.

- Vessel integrity: If the vessels are not compatible with the fluids, then the containment equipment may need to be replaced more frequently to reduce the risk of breaches.

- Product purity and quality: Incompatibility of the container with the fluid could result in leaching from the vessel, impacting product purity and quality further downstream. Although additional purification steps could be introduced to remove any additional impurities, it would be another step that could slow down production and increase costs.

Utilising specialist equipment solutions for liquid handling

Equipment innovation has led to the development of solutions to handle these harsh fluids to assure safety while maintaining product quality. Vessels made of super-alloys allow for efficient liquid handling. These vessels are chemically inert, even for harsh acidic or basic liquids. However, they can be expensive to source, with long lead times for delivery.

As an alternative, specialist plastic mixing, transfer and storage vessels offer a more cost-effective approach. These chemically inert containers, such as those made of FDA or/and USP compliant polypropylene, are effective for storing harsh liquids. As they don’t interact with the materials they come into contact with, the risk of leaching is significantly reduced, eliminating the need for additional purification further down the production line while optimising product quality. Built to withstand harsh materials, these containers are robust for reliable handling over time. Using these vessels, a barrier is formed between the operator and the material, ensuring safety throughout the processing line.

Overcoming sterile challenges

In addition to personnel safety, assuring that a product meets regulatory standards for patients is also paramount. This becomes increasingly complex when manufacturing products aseptically, as in the case of parenterally administered biologics.

Manufacturing biologics is an intricate process, with inherent complexity added by the need for sterility, as these therapeutics are often limited to parenteral administration due to their sensitive nature. As the body’s natural defences are bypassed, the presence of any contaminants in a sample poses a significant risk to the recipient. Sterility must therefore be built into processing lines for the aseptic processing of both liquid and powdered materials to ensure products remain safe for patients.

Many biologic products are lyophilised before packaging to extend product lifetime and increase stability, meaning powder handling, storage and transfer are key components of aseptic processing. The transfer of a product between subsequent stages of production poses the highest risk of exposure to the outside environment and must be carefully considered to meet sterility standards.

Leveraging single-use technology (SUT) for quality and safety

Biopharmaceutical companies must explore possible solutions to overcome the challenges hindering the efficient and effective manufacture of essential materials. The largest risk to sterility in aseptic processing occurs during product transfer, such as moving material between processing lines or equipment.

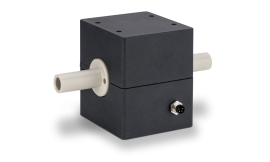

Split butterfly valves (SBVs) enable the transfer of materials between process steps. With SBVs integrated into existing manufacturing lines, powders can be seamlessly transitioned from one stage to another. Although reusable equipment can be used, by incorporating SUT into processing lines, cross-contamination risks are mitigated and the need for validated cleaning procedures is removed.

When coupled with ChargeBags, which can be used for the storage of materials, a closed filling line can be made. Thanks to this barrier between the product and the outside environment, product sterility is assured, allowing for robust storage, transfer and handling of products without exposure.

An effective processing line to meet GMP standards

Navigating biopharmaceutical manufacturing lines to ensure all safety and quality standards are met, irrespective of the drug product, is essential. As a result, both liquid and powder transfer can be required for the manufacture of complex materials. By utilising equipment innovation, production lines can be designed and built with these considerations in mind, helping to ensure operators’ and patients’ needs are met.

Both USP Class IV polypropylene containers and SUT (SBVs and chargebags) can be tailored to fit production, allowing for seamless integration into existing manufacturing lines. Quality is built into the process to meet safety and quality standards as defined by the GMP.

Working with a specialist supplier that has expertise in providing high-performance containers, or SUTs, can aid in navigating the equipment needs to meet the stringent GMP guidelines, maximising efficiency and productivity while ensuring optimum safety for workers and product quality for patients.

Source of Article