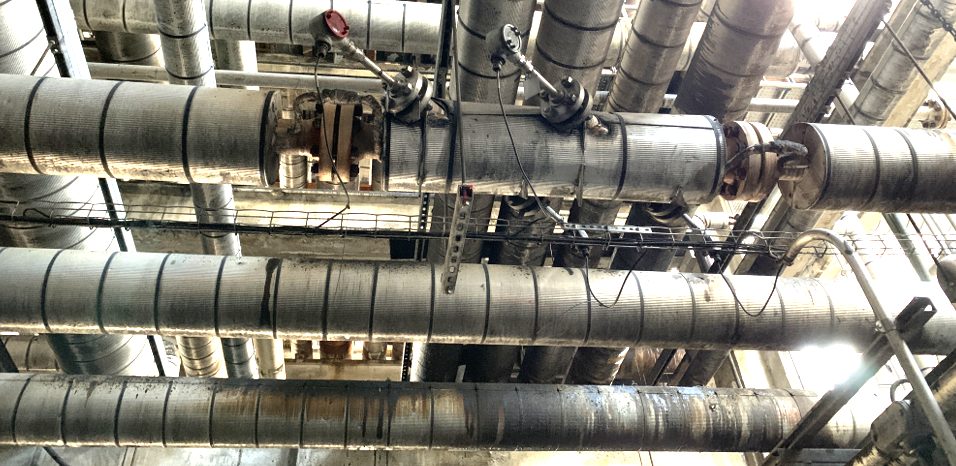

This process unit thermally cracks long hydrocarbons molecules to reduce residue viscosity and increase the oil yield by using fewer middle distillates to get more valuable lighter products.

Existing orifice plates and their differential pressure transmitters were causing countless problems in terms of maintenance, safety and accuracy. These intensive maintenance requirements were increasing the refinery’s OPEX budget.

This application is known to be very difficult to handle, regardless of the selected flow measurement technology, because of the feed from the vacuum distillation unit, heavy residue viscosity and high temperature that is prone to solidify and clog when the temperature reduces.

All competitors using various technologies that tried to address this challenge, failed.

Application

- Medium: Vacuum residue from the VDU

- Pipe size and material: 6” 300# RF P9 ASTM 335 (9Cr 1Mo)

- Flow rate: 20-52m3/h (88-229 GPM)

- Temperature: 300-375°C (572-707°F)

- Pressure: 30-34 barg (435-493 psig)

- Viscosity: 1-2.5 cst at op. temperature

- Requested accuracy: ≤±0.5%

The Visbreaker operates at high temperatures, and it is known to be a severe application with significant safety risks. Indeed, the flow measurement needed to be SIL certified connecting to both the digital control system (DCS) and the emergency shutdown system (ESD) to ensure safe and reliable operations.

In addition to being safety critical, the Visbreaker is also a key unit for the refinery’s overall profitability. Therefore, it is essential to have reliable, accurate and low maintenance flowmeters.

Inaccurate or a lack of flow measurement not only affects the balance of the plant but it can also lead to very high safety risks.

Orifice plates have impulse lines with tubing connecting to the differential pressure transmitter diaphragm that are prone to rapidly clogging due to the build-up of solid residue despite the constant flushing with diesel or distillate.

Panametrics devised a solution for this harsh process condition. The customer tested the Panametrics Panaflow HT 6” 300# R2H in a redundant configuration with one transmitter connected to the DCS and the other to the ESD. Each transmitter used an independent set of BWT/FTPA transducers making the primary measurement also redundant, unlike with an orifice plate. The test occurred on one line with some mechanical work handled during the plant turnaround to install the flowmeter.

The result was good accuracy at extreme temperatures, with virtually no maintenance. The customer simply had to monitor the meter diagnostics and track the trends.

Satisfied that the Panametrics solution was providing accurate and reliable results, the customer has since upgraded its other Visbreaker furnace feed lines. A total of nine flowmeters have been purchased by the customer to increase the process reliability, safety and profitability.

Learn more about Panametrics Flow Meters

Source of Article