Using a temperature-driven “wax motor,” researchers have created an adaptive roof tile system that helps keep a room at a comfortable 18 °C (65 °F). It delivers an extraordinary 3.1X reduction in cooling energy consumption, and 2.6X for heating.

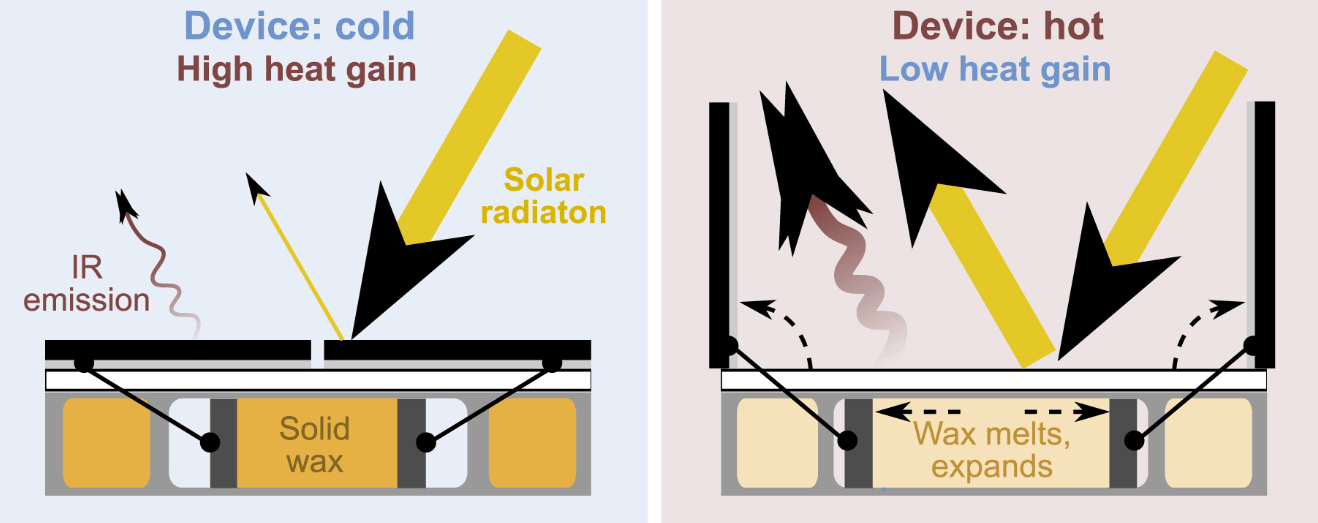

It’s a combination of ideas from mechanical engineering professors at UC Santa Barbara, and it’s very easy to understand. Effectively, it’s a series of louvres that sit on a roof. When closed, these louvres present a flat, black chrome-coated aluminum surface that absorbs heat and doesn’t emit much infrared radiation, thus helping to heat up the space beneath.

When the louvres are opened, a second layer is revealed – this time, painted with a white barium sulfate material known for its infrared-emissive properties and excellent radiative cooling – so it helps draw heat out of the space and send it away.

UC Santa Barbara

But the really neat part here is the wax motor that opens and closes the louvres. Wax expands substantially when it melts, so the team chose a wax with a suitable melting point of 18.2 °C (64.8 °F), and designed a system allowing that expansion to drive pistons that push the louvres open when the wax melts, and pulls them back shut when it solidifies. The wax motors are kept under the roof, so they respond to the temperature in the room.

And that’s pretty much that. The researchers say the louvres fully open and close within a range less than 3 °C (5.4 °F), so they respond fairly quickly as the day heats up or cools down, constantly pushing the temperature towards that 18 °C melting point, whichever way it’s deviating.

Demonstration of adaptive roof tile when exposed to heat

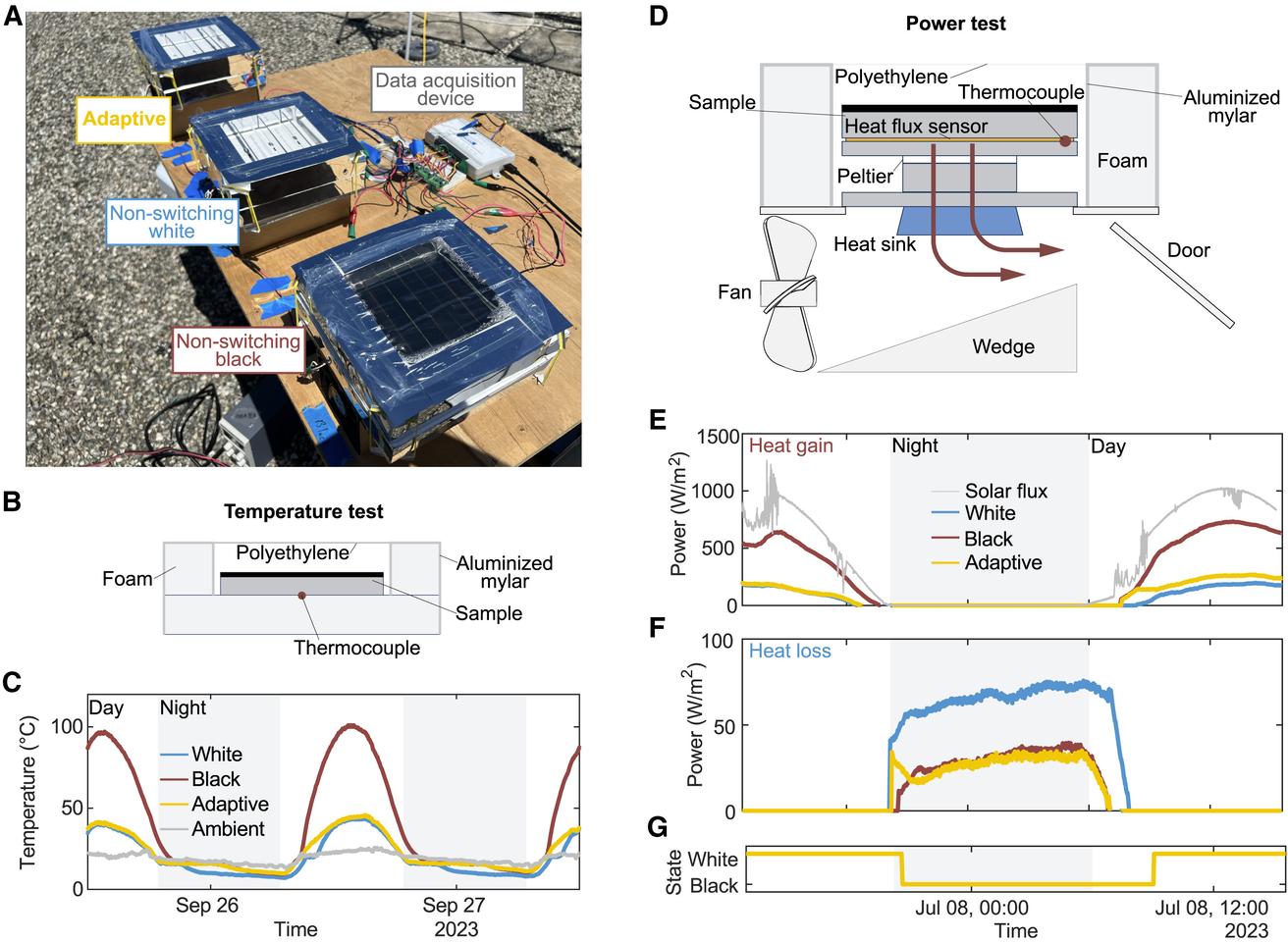

The team tested the adaptive tiles against two static controls – one using the black chrome-coated aluminum surface, and the other using the white barium sulfate paint, and found that at night, it reduced heat loss by a factor of 2.6 as compared with the white tile, and in the heat of the day, it reduced heat input by a factor of “at least 3.1” compared with the static black tile – both these figures measured by the amount of energy needing to be added or removed to maintain an 18.2 °C temperature.

Wax motors themselves are not new; the UCSB team notes they’re commonly used in things like dishwashers and washing machines, as well as in aerospace. But the use of wax motors to drive a temperature control system like this is a new one, with clear potential in passive heating and cooling for buildings.

The wax itself can be chosen with specific goals in mind, says the team, and different thermal coatings might also make the system more relevant depending on where it’s to be manufactured and used.

UC Santa Barbara

“The device is still a proof-of-concept,” said Mechanical Engineering Professor Elliot Hawkes, “but we hope it will lead to new technologies that one day could have a positive impact on energy expenditure in buildings.”

The paper is available in the journal Device.

Source: UCSB

Source of Article