Customer Challenge

New trends in food consumption are reshaping the food processing industry as consumer demand for more variety, both in terms of taste and texture, grows. Take pizza for example, the Italian staple that is now consumed in almost every corner of the world. With almost 5 billion pizzas sold globally each year, it is estimated that the average American consumes up to 46 slices per year, while people in the United Kingdom consume around three slices per week. As its popularity continues to rise, so too does the demand for different flavor profiles and base shapes.

While such demands can often be catered for in a restaurant setting where pizzas are usually made to order, consumers want similar options within the home. Over 200 million Americans – or more than half of the total U.S population – consume frozen pizza at home, and in Europe, the frozen pizza market is expected to reach €9 billion by 2025. As global food producers serving the frozen pizza market look to keep up with the change of pace, new and innovative food processing and manufacturing technologies are being deployed to offer more consumer choices.

FoodJet is one such company bringing new technologies to market. With a long history in engineering and developing high-tech equipment for the food industry, FoodJet has established itself as the world’s first and leading company in precision depositing machinery, offering bespoke solutions for industrial food producers. In response to the demand for more consumer choice, including the need for food producers to supply smaller and more irregularly shaped pizzas, FoodJet developed the MDL pizza sauce depositor – a unique solution that automates the process of applying tomato sauce to pizza bases.

The FoodJet pizza sauce depositor is a high-capacity machine that eliminates the need for manual labor in sauce depositing. As pizza bases are sent to the depositor, the precise contours of each base are captured by a line scanner before the pizzas pass underneath the depositor’s heads. Hundreds of nozzles print the sauce accurately on the bases, ensuring that the precise shape and weight in sauce gets deposited. In comparison, standard showerhead depositors can only distribute sauce to an even shape, which leads to a waste of product and a loss of capital if the shape or position of the pizza bases aren’t uniform.

Xylem Solution

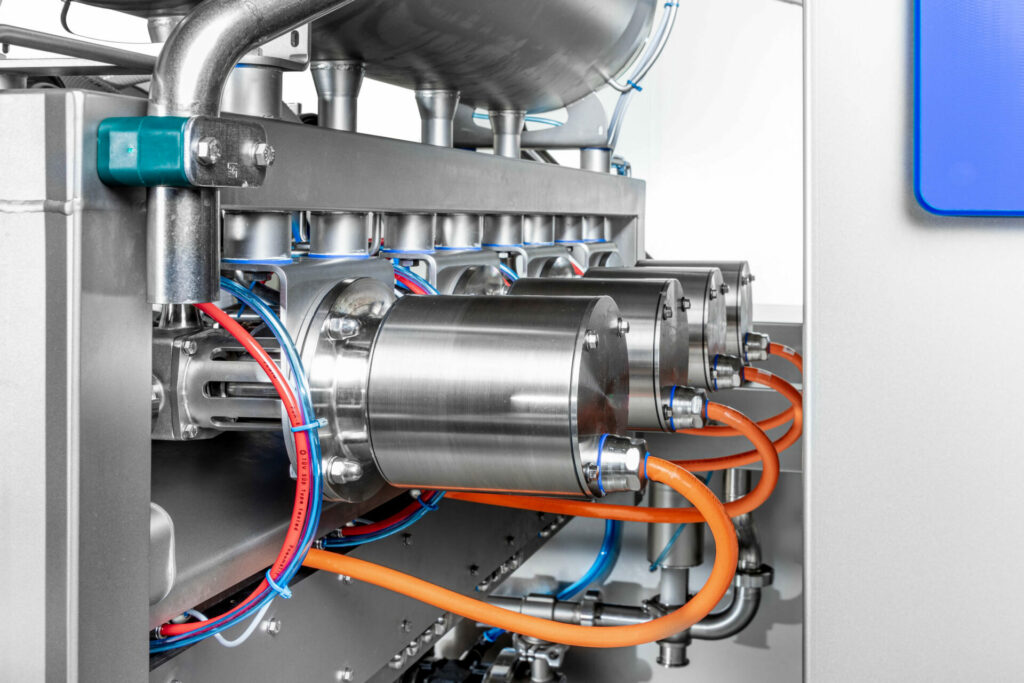

In designing and engineering the pizza sauce depositor machine, FoodJet required a hygienic pumping solution that could deliver a reproducible amount of sauce per revolution while remaining resistant to the active ingredients in sauces and cleaning agents. FoodJet turned to Dutch distributor, Van der Ende Group, to find the right pump for the job. Van der Ende Group identified Xylem’s market-leading Jabsco 28200 series hygienic stainless steel flexible impeller pump (FIP) as the most suitable solution to meet FoodJet’s requirements.

Each FoodJet pizza sauce depositing machine utilizes between one and eight flexible impeller pumps depending on the specific application. The pumps work by pushing the tomato sauce to the depositing heads at the same rate and speed to maintain equal pressure, with each pump serving one depositing head at any given time. As pressure is maintained, the size of the tomato sauce droplets remains uniform throughout the process, and the sauce is deposited on to the pizza bases without impacting its flavor or consistency. Due to the machine’s advanced digital capabilities, each nozzle within the depositing head can be activated individually, allowing operators to choose the specific pattern and volume of sauce each nozzle deposits.

“The way we apply sauce is completely different to any other depositing machine on the market. Our world-first technology has an array of nozzles that can be activated individually, and operators can choose the volume of sauce each nozzle deposits depending on the application specifications. This is done through an advanced computer system that translates the exact contours of the pizza captured during the scanning process into a specific pattern, which is then digitally sent to each nozzle,” said Dirk Schindler, Head of Sales and Marketing at FoodJet.

“Due to the advanced precision of our machines, we needed a reliable, hygienic and efficient solution that will not fail. Thanks to its durability and ability to pump high-viscosity liquids, Xylem’s Jabsco flexible impeller pump has exceeded our expectations, and allows our machines to produce the most perfect pizzas, every time.”

Customer Result

Having launched in 2019, FoodJet MDL pizza sauce depositing machines are sold to industrial food producers globally, including some of the world’s biggest frozen pizza companies. FoodJet recently launched the third generation of the machine, with each generation utilizing Xylem’s Jabsco flexible impeller pumps. Though an established manufacturer of market-leading products for the leisure marine industry, Xylem’s Jabsco brand invented the flexible impeller pump for use in industrial applications more than 80 years ago.

The Xylem Jabsco 28200 Series flexible impeller pump is capable of self-priming from dry up to 5.0 meters (16.4 feet), and can handle a flow rate of up to 40 liters (8.9 gallons) per minute under a pressure of up to 3.0 bar. With the ability to pump a range of viscosities, the pump also handles soft solids with a maximum diameter of 4 millimeters. Easy to service and maintain, with Clean-In-Place (CIP) capabilities, the pump also meets European and US food safety standards for hygienic applications. The pumps are widely used in food manufacturing, dairy production and personal healthcare applications.

“Xylem’s hygienic Jabsco flexible impeller pumps have been designed to meet stringent food contact regulations in multiple markets, making us the only pump provider in the world to offer food-safe products that meet regional standards on a global scale,” said Edwin de Haan, Industry Sales Manager at Xylem.

“FoodJet are a first-class solutions provider, supplying industrial food processing equipment and machinery for some of the world’s biggest brands. We’re proud to partner with them on this innovative solution, and look forward to what comes next as they continue to scale.”

Source of Article