![]()

Fluid flow develops

with the movement of liquid and gaseous materials and pressure sensors play a crucial

role in determining many aspects of fluid flow.

Fluid

dynamics provides the means of understanding the parameters that impact fluid

flow.

In this

context, the term “fluid” refers to either liquid or gases.

Why measure the flow?

In various industrial processes, it is crucial to measure the rate of fluid flow accurately within a system as a whole or in part.

This

applies equally to gases and liquids which are an integral part of the process,

or to compressed air, water or steam which are essential to plant operation.

Flow

describes a wide range of fluid movement, such blowing through the air, flowing

through a pipe, or running along a surface. The flow of a fluid is classified

in a variety of different ways, based upon the various properties of the flow.

A flowmeter

is used to measure the rate of fluid or energy flow to allow the process to be

controlled and so ensure that the end product is of the appropriate quality.

The flow of a fluid can be classified in a variety of different ways, based upon the various properties of the flow.

Fluid dynamics key concepts

Here are

some of the main fluid dynamic concepts when trying to understand fluid

dynamics.

As fluids flow, the density and pressure of the

fluids are also crucial to understanding how they will interact.

The viscosity determines how resistant the liquid is to change, so is

also essential in studying the movement of the liquid. Here are some of the

variables that come up in these analyses:

- Bulk viscosity: μ

- Density: ρ

- Kinematic viscosity: ν = μ / ρ

Reynolds number (Re) is a dimensionless velocity value

used to predict flow patterns. It is a function of the inertia force (ρ u L),

and the viscous or friction force (μ).

Bernoulli’s

Equation (or bernoulli’s

principle) is used to determine fluid velocities through pressure measurements.

It starts with qualifications of non-viscous, steady, incompressible flow at a

constant temperature.

- P + ½ρv2 + ρgy = constant

- P = pressure

- v = velocity

- ρ = density of the fluid

- g = gravity

- y = height

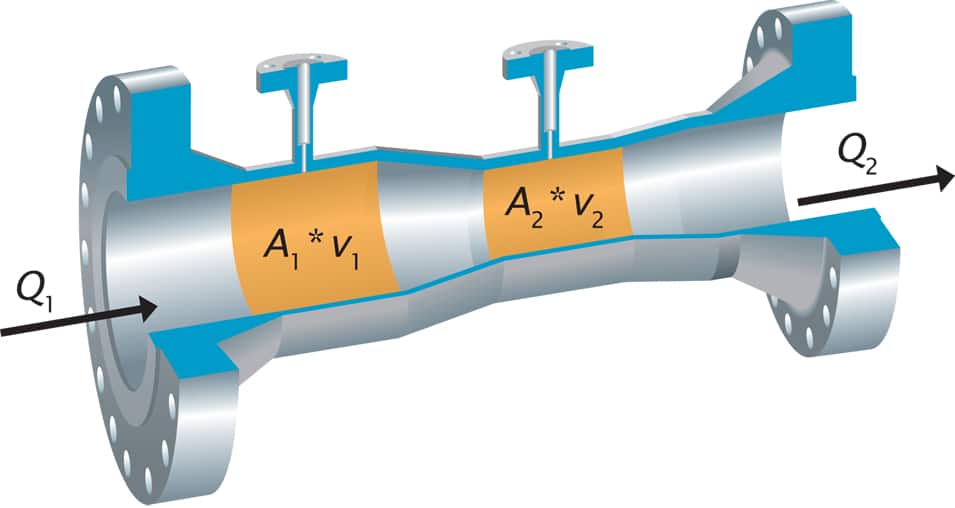

The venturi effect and Bernoulli’s principle

Definition Venturi

Principle: Increase in fluid speed results in decrease in internal pressure.

Because of its

dependability and simplicity, the Venturi is among the most common flowmeters.

The Venturi meter (also known as differential pressure flowmeter) is an application of Bernoulli’s equation.

The Venturi

flowmeter measures a fluid’s flowrate by reducing the cross-sectional flow area

in the flow path and generating a pressure difference.

With no

moving parts or abrupt flow restrictions, the Venturi flowmeter can measure

fluid flowrates with a minimal total pressure loss. A Venturi flowmeter requires

two pressure and one temperature measurement to accurately determine

flow.

Applications Venturi flowmeters:

The Venturi

flometer is used in a variety of industrial applications that include gas,

liquids, slurries, and other processes where permanent pressure loss is not

acceptable.

The Venturi is used in large diameter pipes, that can be found in waste water treatment plants. Because of their gradually sloping smooth design, it allows solid particles to flow through it.

The Venturi

flowmeter can therefor used for applications in which there is a high solids (for

example dirty fluids) content or high pressure-recovery is desirable. It can

also be used to measure fluid velocity.

The temperatures and pressures of chemicals in a pipeline do not affect the accuracy of a Venturi flowmeter and because of this they are also used in crude oil pipelines.

Advantages Venturi flow meters:

- Simple in operation

- Low head loss

- Tolerance of high solids content

- Long-term reliability

- No moving parts

- It can be installed in any direction: horizontal, vertical and inclined

Disadvantages Venturi flow meters:

- Expensive

- Difficult to inspect and maintain due to its construction

- Poor turndown ratio

- Critical installation requirements

Click here for related articles on Flow MeasurementFind manufacturers of flow meters in our Equipment Guide

Sign up for Flow Control and Measurement E-Updates

Source of Article