As the global demand for green hydrogen rises, so too does the demand for efficient and safe flow solutions for long-lasting hydrogen applications. With 60 years of thermoplastic expertise, GF Piping Systems has begun to apply its extensive experience to this dynamic sector, offering a wide range of products and services.

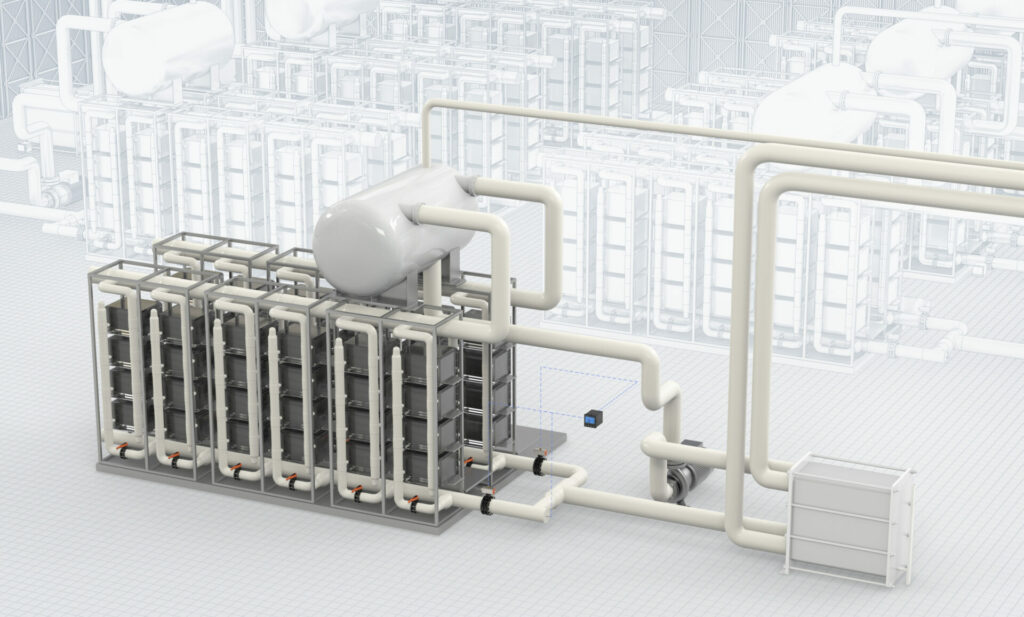

Hydrogen is far from a novel concept, tracing back to its discovery in the late 18th century. However, the advent of green hydrogen production that bridges the intermittency gap often associated wind and solar energy is sparking renewed interest. Piping systems are required throughout the entire green hydrogen value chain, from desalination plants, water treatment, electrolyzers, and distribution to embedded storage and fuel cells. To meet the demands of the industry and drive the cost reduction of green hydrogen, GF Piping Systems aims to increase performance, ensure operational safety, and improve the lifetime of these hydrogen applications.

Within the hydrogen sector, the material selection for piping systems is an underestimated factor. A common challenge in all H2 applications is the need to prevent impurities, and accelerated degradations due to dissolved ions which is a particular concern in metal piping systems. Corrosion and maintenance-free polymer alternatives, on the other hand, can extend the lifespan of systems and components which not only reduces downtimes but also the overall cost of producing hydrogen molecules.

As part of a commitment to support the entire hydrogen value chain, GF Piping Systems is extending its leading polymer expertise beyond desalination and water treatment to collaborate with electrolyzer and fuel cell manufacturers. To serve the need for hydrogen storage, the Swiss flow solutions provider offers high quality injection-molded and extruded tank liner components, made of PE100 and various grades of PA needed as gas barrier for Type IV hydrogen high pressure tanks.

Rachel Bros De Puechredon, Global Business Development Manager Hydrogen at GF Piping Systems, comments: “We are quickly and successfully transferring our extensive expertise in challenging industries such as microelectronics to the hydrogen sector. Thanks to our corrosion-free and chemical resistant components, comprehensive services, as well as our global presence, we believe that we can energize partnerships that shape the sustainable energy transition.”

GF Piping Systems offers a vast portfolio for the safe and reliable transport of gases and fluids and operates 36 production sites as well as 18 prefabrication facilities across 31 countries. This enables the company to provide customers with full project support, from planning and engineering to the installation on-site. Established distribution systems including ELGEF Plus and MULTI/JOINT® 3000 PLUS have already received H2 certifications by KIWA and DBI and are 100% hydrogen ready. In addition, the company is a member of organizations such as Hydrogen Europe, NWBA in NL, and DVGW in Germany.

Source of Article