Hawk Measurement Systems (HAWK), the world leader in level, positioning, asset monitoring and flow measurement, has designed and developed the industry’s first in-plant and cloud-based measurement and monitoring system, HawkEye365.

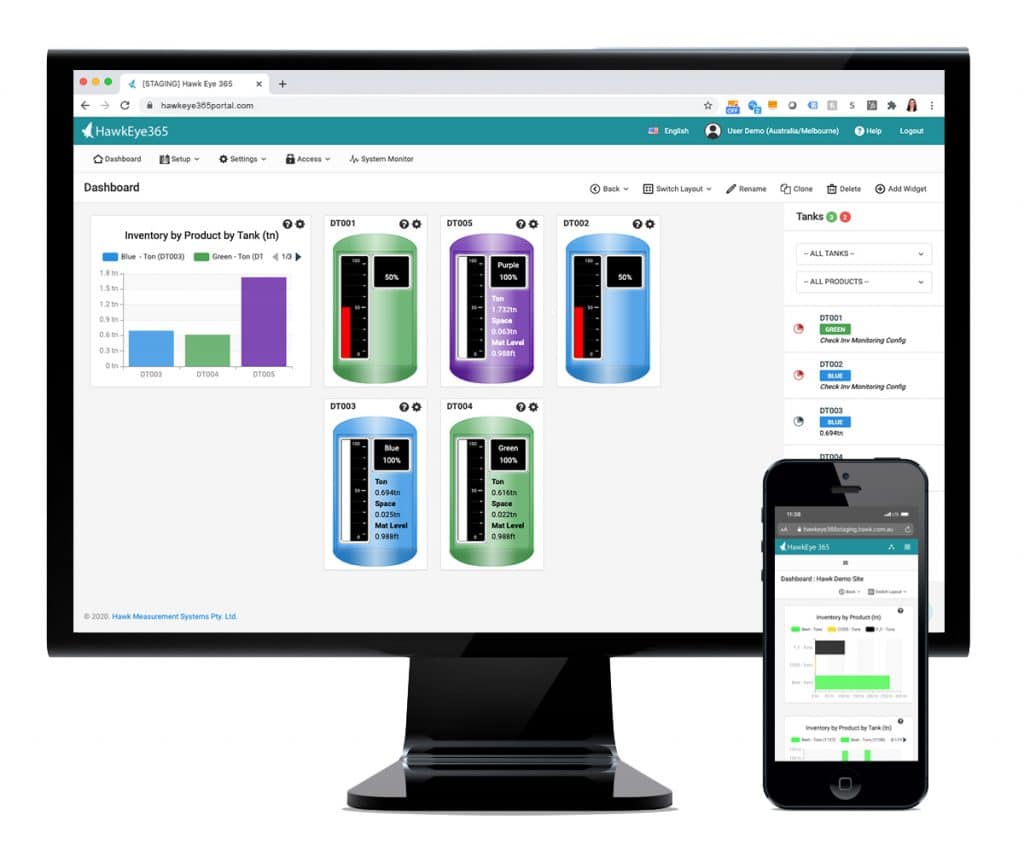

The HawkEye365 Online Inventory Asset and Monitoring Portal is a complete remote and in-plant measurement and system. Unlike anything on the market today, this system is uniquely different due to the communications capabilities and compatibility with Power over Ethernet (PoE) level sensors. The advantages to Power over Ethernet connectivity are secure in-plant and remote monitoring as well as remote sensor setup, diagnostics and troubleshooting abilities. The HawkEye365 portal not only monitors PoE transmitters but is sensor agnostic and can monitor any type of field device such as level, flow, pressure, temperature and pH. The multiple communication methods include RS485, HART, Modbus, Ethernet TCP/IP, Cellular, Bluetooth and PoE.

Jack Evans, President of HAWK, explained that the decision to design and develop an innovative monitoring technology such as HawkEye365 was necessary based on their customer feedback and foreseeable direction of the market. Evans added that, “HAWK has been providing innovative sensor technologies for over 30 years in some of the harshest environments. HAWK has provided remote service capabilities for many years now and has developed remote monitoring of assets with the ability to provide remote service. The HawkEye365 is designed for expansion to uplink data to unlimited facilities and unlimited remote sites. HAWK is committed to providing innovative technology and services to customers globally.”

The HawkEye365 Online Inventory Asset and Monitoring Portal has the ability to monitor multiple tanks and applications worldwide in real-time. The portal provides accessibility to critical data such as the ability to view volume, space, material height, historical trending, alarms and alerts, sensor setup and diagnostics. Plant level operator screens are customized to the company’s specifications to include control room level and operations level interface screens. The graphical user interface will be common throughout and permissions can be set for different tiers such as plant-level, finance or executive level. If any troubleshooting is required, the HawkEye365 will communicate to remote service technicians for off-site diagnostics, sensor health and re-configuration, without the need to climb a tank or enter the facility.

Inventory asset management is becoming more critical throughout many process industries such as oil & gas, chemical & petrochemical, water & wastewater, energy, mining, and agriculture. It is imperative to implement reliable technologies to monitor and manage valuable commodities and inventory assets. Over the past 30 years, HAWK has been the trusted name for level, positioning and flow measurement solutions in the process instrumentation market and is now adding remote and in-plant asset monitoring to their high-quality systems and solutions.

Click here for more informationClick here for related articles and news

Sign up for Level Control and Measurement E-Updates

About HAWK

Hawk Measurement Systems (HAWK), the world leader in level, positioning, asset monitoring and flow measurement technology, provides cutting-edge equipment and complete solutions to the global industrial market.

Established in 1988, HAWK has won several prestigious …

Source of Article