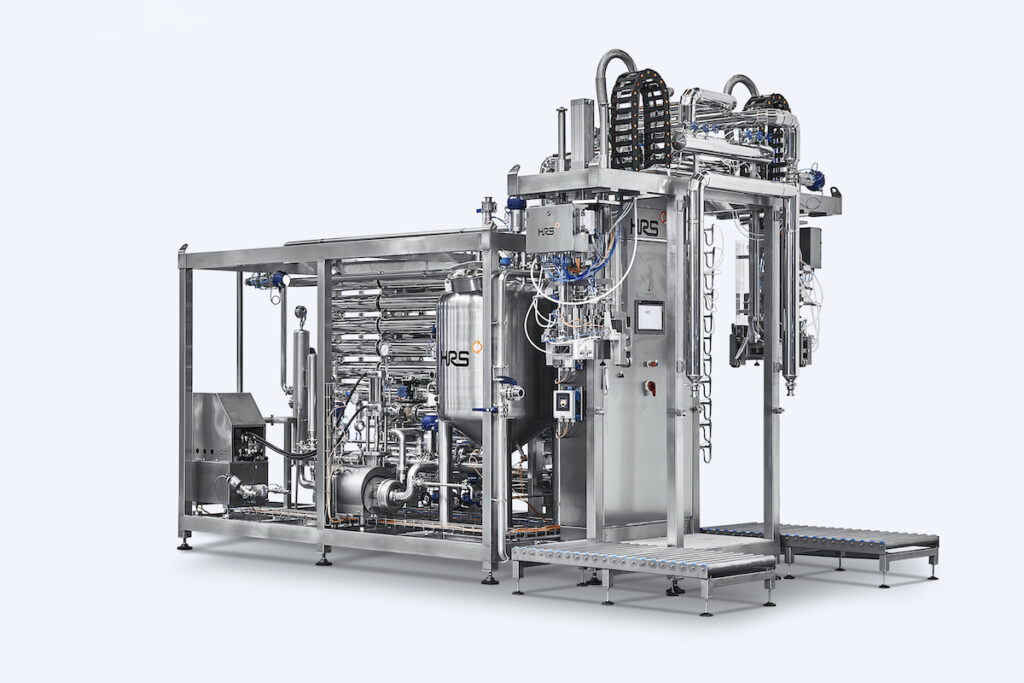

In response to demand from customers across a wide range of sectors, from fruit juice makers to meat processors and dairies, HRS has now developed a wide range of turnkey line solutions, which are successfully being used by food processors worldwide. At Anuga FoodTec 2024, the company will showcase its range of complete all-in-one solutions, including pasteurising, sterilising, aseptic filling and clean-in-place capabilities in a single system, as well as options which can be skid-mounted for easy installation.

Other HRS systems for the food and drink sector include deaeration systems, the I Series of ice crushers and melters, direct steam injection sterilisers (DSI Series) and dedicated CIP and SIP systems. The company also provides systems for customers to conduct product and processing trials before committing to a final production solution.

Unlike some providers that only sell standard options, each HRS product is designed to the client’s individual needs, meaning customers can be sure of getting the right system first time around. And although clients are increasingly looking for all-in-one solutions, HRS continues to supply individual heat exchangers and other products (such as its BP series of hydraulic piston pumps and AF series of aseptic fillers) across the food sector.

HRS Heat Exchangers, Hall 4.1 – Stand A080, Anuga FoodTec 2024, Cologne, Germany

Source of Article