With over 40 years of experience from over a million successfully solved applications in the bulk solids sector, UWT has in recent years expanded into liquid measurement management with new innovative product lines. With the addition of the new liquid measurement sensors UWT is now able to offer complete solutions for wet and dry level management.

Technology explained

Inverse Frequency Shift Technology on board for precise measurement results

What is special about our capacitance line is the unique Inverse Frequency Shift technology. Not the capacitance is measured but the frequency. As we are measuring the frequency even small changes can be detected which means high accuracy, sensitivity and precise measuring results.

Robust construction, versatility and ease of use

The sensors are equipped with potted electronics providing a robust, certified construction. They offer measurement solutions for a wide variety of liquids, pastes and foams – whether to be used for aggressive chemical applications, within the demanding food industry or in wastewater handling. Through a variety of metal rope, cable, rod and pipe extensions the units can be easily adjusted to each application.

Tip Sensitivity & Active Shield technology copes easily with material prone to caking

Capanivo® CN 7 and CN 8 level detectors are equipped with Tip Sensititive Technology whereas the RFnivo® RF 8 and NivoCapa® NC 8 devices benefit from Active Shield Technology, both ensuring precise measuring results even when detecting media that tends to stick to the probe. This offers a great advantage over conventional sensors. Despite strong adhesion or bridging between the sensor tip and the container wall, precise measurement results are output.

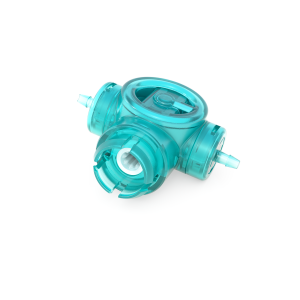

Feature packed sensors – choosing the right product for the application

When space is at a premium the compact design of our Capanivo® 7000 is the product of choice, available as enclosure model made of stainless steel or synthetic or as an integral cable version. The Capanivo® 8000 on the other hand is an all-round talent due to its range of process connections, hygienic versions and high safety standard. The robust RFnivo® 8000 that includes a high-temperature version for a wide temperature range from -40°C to +400°C and pressure resistance up to 35bar. The PFA isolation ensures a high degree of chemical resistance.

The NivoCapa® 8000 measures the continuous level in conductive and non-conductive materials with pinpoint accuracy. At the same time the LCD display with control buttons and diagnostic function make the level sensor very user-friendly.

Practical Tests with the compact CN 7

If you look at the whole thing in practice, it becomes clear how versatile the capacitive measuring principle is in very different liquids. The example of measurements in honey, beer and a water-oil layer illustrate the flexible use in media with different requirements:

Level sensors handling heavy caking material

For viscous or sticky materials, such as honey that tends to stick, UWT uses the Tip Sensitivity technology for the capacitive level sensor Capanivo® 7000. This ensures that the sensor switches reliably even if heavy buildup is present. The limit switch can reliably detect the honey because its sensitivity is very high and can detect material with a DK value below 2.

Level measurement of light beer foam – detection of liquid and foam possible!

However, the Capanivo® 7000 can also be used for the detection of very light beer foam. Both the beer and the extremely light beer foam are detected perfectly – the sensor detects exactly which medium is to be measured. Compact and flexible, it determines the limit level in both metallic and non-metallic containers.

Interface measurement

Regardless of whether oil and / or water is to be detected – the sensor can measure both reliably. As a capacitive sensor, it reacts to changes in capacitance on the probe arm when it is touched by a medium and then switches a signal output. The active approach compensation makes it insensitive to material deposits on the probe.

Smart solutions for exciting applications

The range of applications in the liquid sector offers a world full of exciting applications in a wide variety of industries. With more than 1 million successfully implemented customer applications and the innovative capacitance range of detectors for level and point level measurement, UWT is ideally equipped with smart solutions in all liquid areas.

Click here for product informationClick here for related articles and news

Sign up for Level Control and Measurement E-Updates

Solution partner for level measurement since 1977 with comprehensive expertise in all industries and process applications. UWT is a medium-sized German family owned business and has become one of the world’s leading experts in the field of level measurement technology offering innovative sensors for continuous and point level measurement in any …

Source of Article