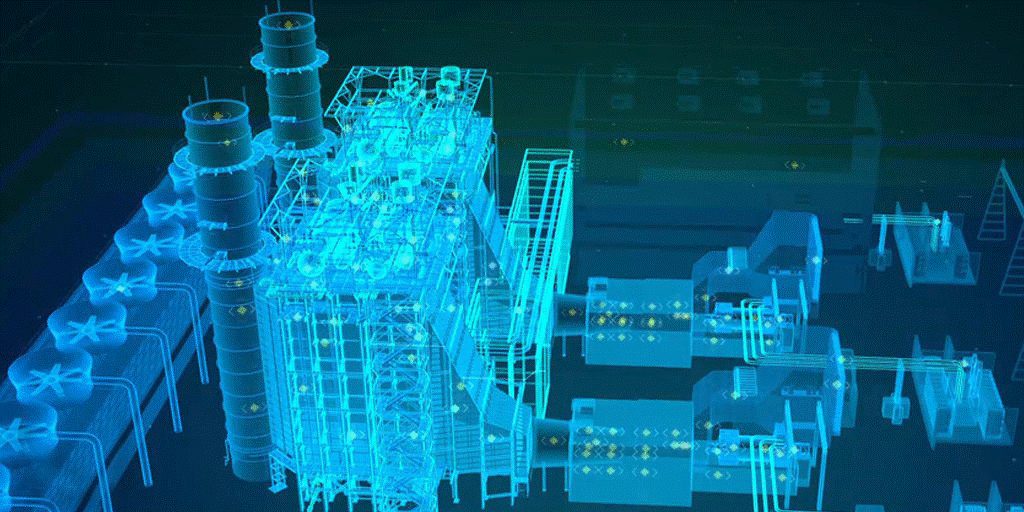

In today’s rapidly evolving industrial landscape, integrating the Internet of Things (IoT) and Industry 4.0 technologies has ushered in a new era of efficiency, intelligence, and optimization within industrial fluid handling applications. These innovations have fundamentally transformed how fluids are managed, monitored, and optimized, offering myriad benefits to industries relying on fluid handling systems.

IoT, characterized by interconnected devices, sensors, and systems, along with Industry 4.0’s focus on automation, data exchange, and intelligent manufacturing, have converged to revolutionize the way industrial fluids are processed, transported, and utilized.

Real-Time Monitoring and Data Analytics

One of the pivotal advancements stemming from IoT and Industry 4.0 integration is the ability to gather real-time data from various sensors embedded within fluid handling systems. These sensors monitor crucial parameters such as pressure, temperature, flow rates, and chemical compositions. The collected data is then transmitted and processed through interconnected networks, enabling comprehensive monitoring and analysis.

This real-time monitoring capability allows for predictive maintenance, early fault detection, and optimized system performance. By leveraging data analytics, anomalies can be identified swiftly, leading to proactive interventions before issues escalate, minimizing downtime, and optimizing operational efficiency.

Predictive Maintenance and Enhanced Efficiency

Predictive maintenance made possible through IoT integration, has transformed maintenance practices in industrial fluid handling. Machine learning algorithms predict potential equipment failures by analyzing historical and real-time data patterns. Maintenance schedules are optimized, and interventions are planned accordingly, reducing unplanned downtime and maximizing the lifespan of critical components.

This proactive approach saves on maintenance costs and ensures a more reliable and efficient fluid handling system. Additionally, intelligent systems can fine-tune operations in real-time, adjusting flow rates or mixing ratios for optimal efficiency based on current conditions.

Remote Monitoring and Control Systems

IoT and Industry 4.0 technologies have extended the capabilities of remote monitoring and control in fluid handling applications. Operators can remotely oversee and manage fluid handling processes through cloud-based platforms and interconnected systems from virtually anywhere. This capability enhances operational flexibility, allowing for prompt adjustments or interventions without needing physical presence on-site.

Remote monitoring also facilitates centralized control of multiple systems, enabling better resource allocation, uniformity in operations, and the ability to address issues promptly across diverse locations.

Improved Safety and Compliance

The integration of IoT devices and intelligent sensors ensures a heightened level of safety and compliance in fluid handling applications. Real-time monitoring of critical parameters enables the immediate detection of deviations from safety thresholds. Alerts and automated shutdown systems can be triggered in hazardous conditions, preventing potential accidents or environmental hazards.

Moreover, these technologies facilitate compliance with regulatory standards by providing comprehensive data records and reports, ensuring adherence to stringent industry guidelines and environmental regulations.

Future Outlook and Challenges

As industries continue to embrace IoT and Industry 4.0 integration in fluid handling, challenges such as cybersecurity threats, interoperability issues, and data standardization must be addressed. Robust cybersecurity measures are imperative to safeguard sensitive data and prevent unauthorized access or system breaches.

Furthermore, ensuring compatibility and seamless integration of diverse systems and devices from different manufacturers is crucial for maximizing the potential benefits of these technologies.

In conclusion, integrating IoT and Industry 4.0 in industrial fluid handling applications has redefined operational paradigms. Real-time monitoring, predictive maintenance, remote control capabilities, enhanced safety, and regulatory compliance are among the manifold benefits these innovations offer. With ongoing advancements and concerted efforts to address challenges, the trajectory of fluid handling industries is poised for further optimization, efficiency, and sustainability through the convergence of these cutting-edge technologies.

Source of Article