The foundation of modern radar level measurement was laid with non-contacting microwave radar technology. Operating initially within the frequency range of 6 GHz, 9 GHz, and later 26 GHz, these radar transmitters utilized electromagnetic energy propagation emitted from a horn antenna. Their key advantage lay in their ability to provide reliable measurements in challenging environments, including heavy vapors, steam, and high temperatures.

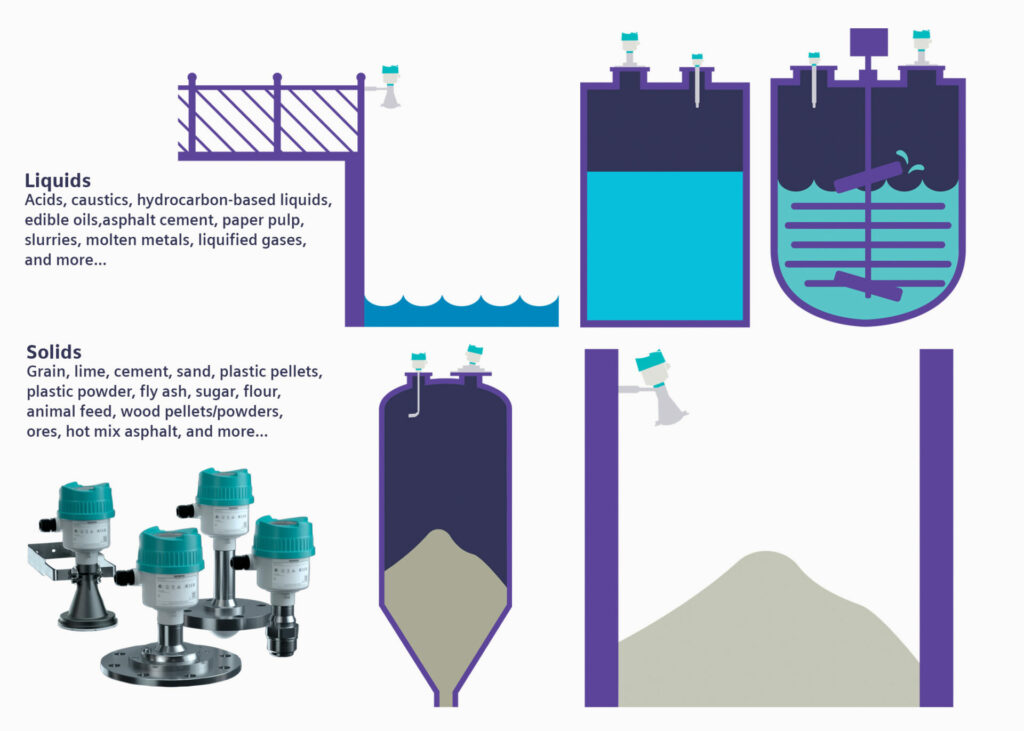

In liquid applications, these radar transmitters excelled by transmitting microwave energy through stratified vapor layers, ensuring accurate readings regardless of temperature differentials. Similarly, in solid applications such as grains, cement, or powders, they operated effectively, even in environments with heavy dust particulates.

The Frequency Buzz: Pushing Boundaries

As radar technology advanced, frequency became a focal point of discussion. The release of radar transmitters operating at 78 GHz (80 GHz) in 2011 by Siemens marked a significant milestone. This higher frequency opened doors to new possibilities, especially in solids level measurement, where material irregularities and extreme dust conditions posed challenges for mainstream radar transmitters.

The higher operating frequency addressed gaps or challenges in special circumstances, such as signal skipping or geometric limitations in silos or tanks. Granular materials like sugar, silica sand, or frac sand became challenges of the past and were easily handled with the newer radar technology. Additionally, the tight 4-degree beam angle facilitated installations in less-than-ideal process connections, thereby reducing retrofitting costs.

Open Air Challenges: Regulatory Hurdles

While radar technology evolved, regulatory hurdles persisted for outdoor use in open-air environments. Proposed rule changes aimed to allow radar devices to operate both outdoors and inside storage tanks across specific frequency bands. However, navigating the regulatory processes, including FCC reviews, proved slow and arduous.

The FCC approved some LPR for open-air use but restricted radar transmitters to a beam angle of 12 degrees or narrower. Radar transmitters operating at 80 GHz, with a 4-degree beam angle, are allowed in open-air applications without restrictions, but never aimed at the sky. Installation in open air application applies to the SITRANS LR500 series, which has beam angles ranging from 3 to 10 degrees, making them suitable for various environments beyond closed tanks and silos.

Present and Beyond: Introducing the LR500 Series

Transcending regulatory discussions and technological advancements, Siemens released the SITRANS LR500 series radar transmitters, epitomizing precision, and performance. With 1 mm accuracy, a measurement range extending up to 394 feet, and a rapid response of up to 3 measurements per second, these transmitters set new standards in level measurement.

Equipped with Process Intelligence, the SITRANS LR500 series continuously adapts to changing conditions, ensuring optimal performance in diverse solids and liquid level applications, including turbulent process conditions or when materials exhibit low reflectivity properties. Features like easy setup with Quick Start Wizards, Dynamic TVT threshold curve, and Near Range Suppression elevate the level measurement experience, guaranteeing reliability and accuracy.

Additionally, Siemens introduced SITRANS IQ Guard, a smart application suite that manages device health, data accuracy, and standard conformity, ensuring profitable, secure, and sustainable operations. It offers comprehensive diagnostics, monitoring, and verification through smart field devices and advanced diagnostics, logging various process values, automatic near range suppression to negate antenna buildup, and signal quality monitoring that can trigger actions such as engaging defoaming agents for problematic materials. This allows users to maintain device health and determine optimal operation and maintenance timing effortlessly.

Conclusion: Embracing Innovation

The evolution of radar level transmitters underscores the relentless pursuit of innovation to address industry challenges. From non-contacting microwave radar technology to advanced precision with the LR500 series, each milestone represents a leap forward in performance and reliability.

As we embrace the latest advancements, we reaffirm our commitment to providing optimal level measurement solutions that empower industries worldwide. With radar technology at the helm of innovation, the future holds endless possibilities, promising greater efficiency, sustainability, and reliability across all process industries.

Source of Article