In a water-cooled mold, like those used to manufacture parts for the aerospace, automotive, food and beverage packaging industries, keeping the temperature of the mold consistent is critical for producing consistent parts.

Using a product like the Proportion-Air FCV flow control valve allows for tight control of temperature by proportionally controlling the flow of cooling water with a command signal from a PLC. By controlling upstream water from the chiller, manufacturers can precisely control flow for a consistent, high-quality molded part. The FCV is electronically controlled, providing a position proportional to the command signal and perfect for cooling a mold with water.

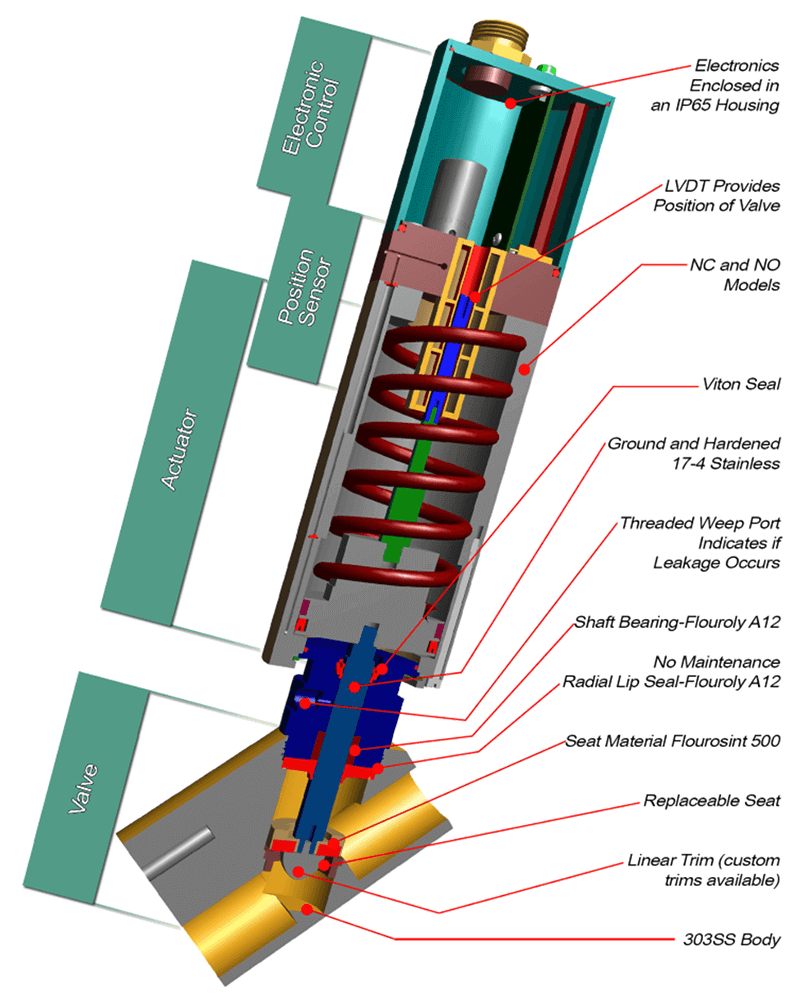

Understanding the FCV

The FCV is a 1″ electronically controlled angle seat valve with a parabolic seat. The parabolic valve seat/plug geometry means the area of valve opening is proportional to valve position. This happens courtesy of either a 0-10 VDC or 4-20 mA command signal proportionally controlling the position of the plug/seat, which in turn controls the size of the opening. It compares the command signal input from a customer’s computer or PLC with feedback from a built-in electronic linear variable differential transducer (LVDT). The output is linear and directly proportional based on command signal input.

For example, if valve position is 50% of full stroke, Cv is 50% of maximum rating. Valve position is electronically closed-loop controlled, with the LVDT providing continuous feedback to the control module. The LVDT and control module are integral to the valve actuator. The FCV comes with a monitor output signal. This output is an electrical signal originating for the internal LVDT, 0-1” stroke. The output of this signal is field selectable, 0.5-10Vdc or 4-20mA. The FCV features status indicating LEDs for power and TTL. The TTL signal is a conditional on/off signal to use for diagnostic purposes. When the valve is at position, the TTL is active low (0Vdc) and the green LED is ON.

With a max Cv of 19 and the ability to handle pressures up to 250 PSI, the FCV controls hydraulic media in a closed-loop proportional CV device without the need for an external flow meter. Flow can be calculated by using the valve position and the differential pressure across it.

The FCV is a high-resolution device, providing a resolution of ±0.3 percent of a full stroke (full stroke = one inch). Made of 316 stainless steel, it offers ±5% linearity.

This rugged device can also replace traditional process control valves to offer more precise Cv control.

Maintenance Advantages

The FCV offers maintenance advantages over other angle seat and process valves. Rather than standard packing, a double radial lip seal maintains the integrity of the device. A weep detection port indicates when the seal needs to be changed, an easy process requiring only a wrench and a few minutes to change the leaky seal. The valve seat is also replaceable. If any damage occurs, a new seat can be ordered and installed. Other valves with damaged seats often require full replacement.

Source of Article