![]()

Merriam-Webster defines the term as follows, “to undergo a reduction to an optimal size”.

As an example, let’s apply this term to gardening. In the fall season, you prune and shape your plants. Although this may be extra work, come spring the plants will be healthier and visually appealing. This is the positive connotation and concept we’re looking at today. The difference is that, instead of applying this to garden plants, we are applying it to industrial plants. Instead of gaining healthy flowers, you’ll gain a healthier maintenance budget.

As we all know, the economic climate has changed radically in the past year. This overall industrial shift has spurred adjustments within the instrumentation market. Users are increasingly interested in finding ways to stretch their budgets while ensuring efficient measurement and maximum production output. This means analyzing the cost and reliability of their instrumentation as well as choosing the most efficient product for the application.

The Scalability Solution

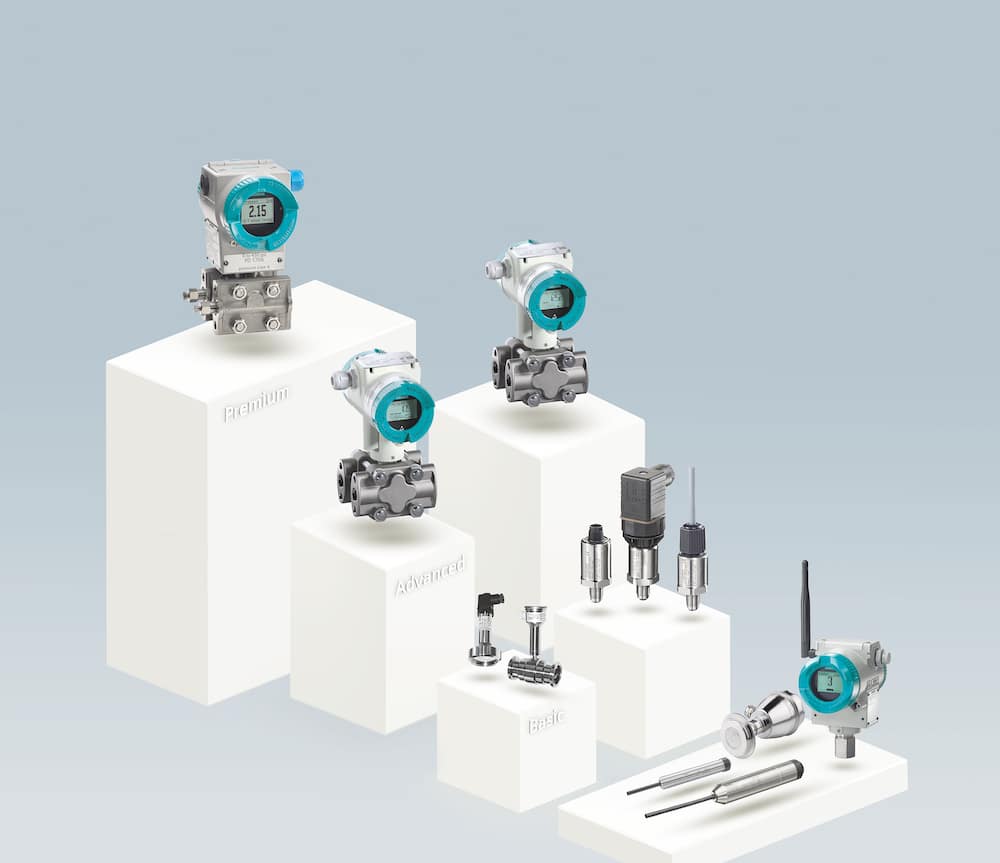

Every measurement application is different and because of that, users require measurement solutions tailored to their needs. The scalability solution fits into that mold. It enables the ability to expand and contract to accommodate different or changing needs. With this solution in mind, Siemens has introduced two new transmitters to its SITRANS P Pressure Portfolio – the SITRANS P320 and P420. These new transmitters replace the basic (P310), Intermediate (DSIII), and advanced (P410) pressure transmitters and are upgrades in every way, without an increase in price.

The new SITRANS P320 and P420 introduce an all-new local user interface to the pressure family. The always-included 4 magnetic pushbuttons allow for the configuration of measuring range, zero correction, scaling for level or flow, and many more parameters, all without the need for digital communication tools. These parameters are accessed through an all-new text-based menu structure. This user interface is shared with other new devices in the Siemens portfolio. Once you know how to operate one, you will be able to easily work with the latest level, temperature, and valve positioning technologies.

The SITRANS P320 replaces the DSIII pressure transmitter in terms of performance. It offers the same accuracy (0.065%) while improving response time and long-term stability. However, it does this at a price point that matches the basic P310 pressure transmitter.

The SITRANS P420 replaces the P410 pressure transmitter with an accuracy of 0.04% but adds features for the world of digitalization. On-board trend logging of up to 1500 data points allows for the export of historical process and diagnostic data. This information can be transmitted to your DCS or to the cloud for app-based process monitoring and analysis.

In addition to these, Siemens offers a Premium differential pressure transmitter, the P500. It features a 0.03% accuracy as well as a turndown ratio of 200:1. The P300 is our hygienic transmitter featuring SS construction, hygienic connections, and CIP/SIP ratings. Our SITRANS P200 line offers basic measurement capability, space-saving construction, and a wide range of connections and pressure spans. Finally, submersible pressure transducers, the LH100 and LH300, allow for level readings as small as 3 feet and up to 530 feet, with cable lengths that can reach over half a mile.

When we look at specific pressure measurement applications, we recognize that each one requires a different level of accuracy and speed of response. With the upgrades and expansion of the Siemens SITRANS P Pressure Portfolio users can scale or choose different transmitters to fit each application, while meeting (or exceeding!) performance requirements and reducing the total cost of implementation.

Conclusion

In conclusion, rightsizing your pressure applications by scaling the equipment you’re using allows you to reduce unnecessary expenditures while maintaining the best class of measurement for each application. When you partner with Siemens to implement this concept, we will help select the right product, while bringing knowledge of the applications, installation expertise, and full breadth of automation systems and equipment.

Click here for related articles and news

Sign up for Pressure Control and Measurement E-Updates

Siemens brings you an innovative portfolio of process instruments for flow, level, pressure and temperature measurement, as well as a wide range of continuous weighing products. Pneumatic valve positioners, process controllers and recorders, and process protection devices complete the package. Our versatile technologies meet the needs of diverse applications …

Source of Article