![]()

Process plant engineers conduct a sizing analysis to determine whether a selected control valve has the appropriate flow capacity and operating characteristics to provide the intended process control. Typically, end user control valve sizing is done in accordance with international standards, and the steps outlined by ISA, ANSI, and IEC.

During the sizing process, plant engineers must avoid choosing an undersized valve, since this would result in process inefficiencies and lowered production. An oversized valve also comes with disadvantages, including poor process control, the need for larger actuators, and unnecessary additional weight and cost.

Challenge:

The Shutter Valve™ is an ideal solution for control valve applications and is especially well suited to perform the same functions as globe valves. However, the Shutter Valve represents a step change in valve design. As such, any new and unique technology can face many barriers to adoption, such as anticipated switching costs and a lack of end user familiarity with performance characteristics and potential applications.

The challenge for Clarke Valve™, therefore, is to ensure that the different sizes and pressure classes of the Shutter Valve correspond to commonly available globe valve sizes, and that the CV coefficient, pressure drop, and other performance characteristics are also appropriately matched. Cycle testing also needs to be performed, to ensure reliability.

Solution:

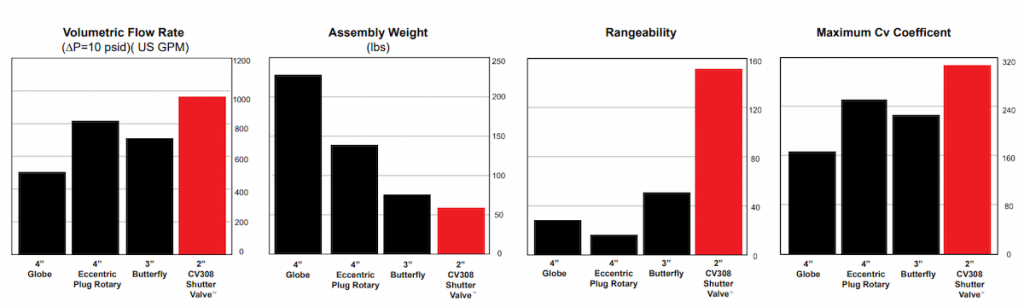

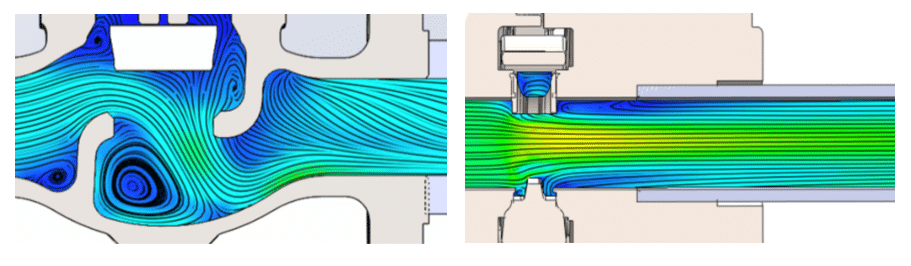

To begin with, the unique geometry of the Shutter Valve means that it can deliver a CV equivalent to a much larger globe valve. The centralized flow stream produced by the aperture of the Shutter Valve allows for superior process control, while also providing for full port operation with zero pressure drop.

During our process of research and development, we reviewed publicly available performance data for many globe valves, and cross referenced this information with our own testing results. For example, even though the CV71 Shutter Valve has a 1-inch port, it can effectively replace 2-inch, 3-inch, and 4-inch legacy globe valves in many applications.

Across our entire product line, the Shutter Valve delivers equal or greater CV and other desirable performance characteristics to effectively replace much larger globe valves, at each size and pressure class.

Beyond the unique performance characteristics of the Shutter Valve, the fact is that most globe valves are oversized for their respective applications, due to the inefficient geometric configuration that the globe valve employs to throttle the flow of control fluids. For example, a 12-inch globe valve may only have a 4-inch port. So, to achieve the desired flow rate and pressures for a given process, a very large, heavy, and expensive globe valve is required, when a 4-inch port (CV1345) 12-inch Shutter Valve can handle the same job at 1/5th to 1/2 the size, weight, and cost. The actuator needs are likewise, much smaller for a Shutter Valve than an equivalent globe valve, as the aperture of the Shutter Valve opens perpendicular to the flow of any controlled fluids, and therefore requires substantially less operating torque.

While the comparative assessment of the Shutter Valve against various globe valve sizes is a helpful benchmark, we nonetheless carry out a comprehensive sizing analysis for any potential valve installations, both new and retrofit. We will consider the CV rating required and the corresponding percentage that the valve is open to allow the flow and pressure drop that the process needs. Clarke Valve will also run a computational fluid dynamics (CFD) analysis to ensure that the Shutter Valve does not create any detrimental fluid effects for the end user’s process.

Results:

The Shutter Valve can provide greater value than most globe valves, by delivering the same valve characteristics (flow rate, pressure drop, etc.) from a smaller, lighter weight, and less expensive valve and actuator package. This provides a major impact and incentive for an industry that spends $7B annually on control valves. The reduced size and weight of the Shutter Valve and its actuator also makes it easier to install and service, conferring proven labor efficiencies and lower total cost of ownership on any facility that deploys the Shutter Valve for process control.

Click here to learn more about the state-of-the-art Shutter Valve technologyClick here for related articles and newsSearch for valve manufacturers in our equipment guide

Sign up for Process and Control Valves E-Updates

Clarke Valve was founded in 2011 by Kyle Daniels in Miami, FL, a descendant of the Miami Beach pioneering Clarke family. Mr. Daniels named his company after his great uncle, Gerald Clarke, who gave his life serving in the U.S. Army in World War II. Gerald Clarke was a brilliant mechanic and inventor. Kyle Daniels developed the technology behind the …

Source of Article