![]()

How to optimize the inline blending process, ensure product quality and save costs.

With a refractometer you can optimize the inline blending process, ensure product quality and save costs in the juice or beverage production. In applications, the inline Brix analysis of products enables automated, highly accurate process control and quality monitoring.

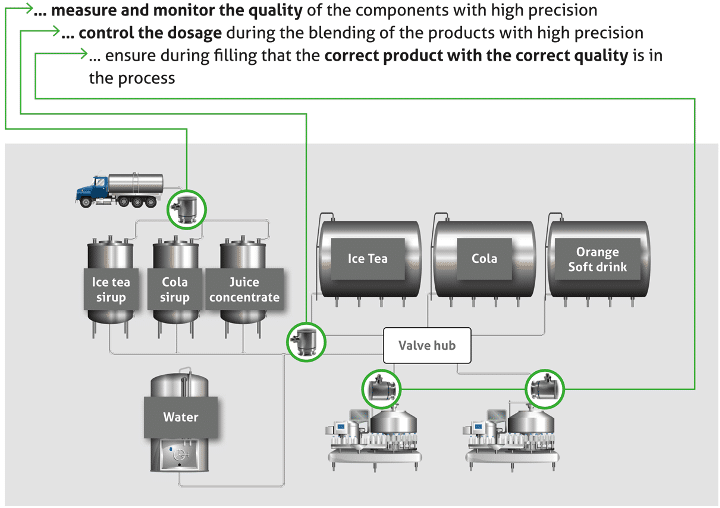

When blending and filling juices, syrups, nectars, soft drinks, and other beverages the refractometer can:

In beverage production, syrups, juice concentrates, or other components are usually blended with water according to specified recipes, then stored in stacking tanks, and finally filled into bottles or containers, which are often product specific.

If a preliminary component, e.g., a juice concentrate, does not precisely meet the specifications or if the blending process itself is incorrect, e.g., caused by a wrong valve switching, the entire product may be defective.

It is also possible that the wrong product is bottled due to incorrect phase transition. If this is only detected during the final quality control, a complete production batch may have to be disposed of.

With a refractometer, each process step can be controlled by measuring the dissolved sugar in the liquid. If this Brix-control is made with manual samples and hand refractometers, this requires a very high workload for the personnel, e.g., every 20 minutes. In addition, an error can only be detected afterward, so that the production quantity between two samples or a complete filling batch can be affected and must be disposed of.

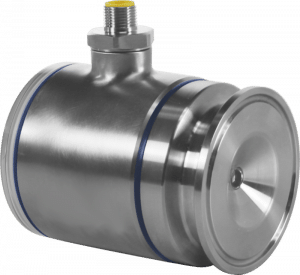

The IRM-11 refractometer is integrated into the process and measures the Brix value, which is the concentration of dissolved substances in the products such as sugar, with high accuracy and continuously. This allows to define and differentiate each component or product.

Three essential features of the IRM-11 are the basis for its highly efficient process analysis:

- The measurement is inline, temperature compensated, and continuous (measuring interval adjustable from 2 s). This saves labor costs for manual sampling and ensures correct measurement results in real-time.

- When measuring manually, the entire manufactured product between two measurements can be defective. IRM-11 can avoid these product losses due to its permanent measuring method

- The compact, all stainless-steel design, and the simple, flush installation without bypass ensure maximum operation dependability in all applications.

-

IRM-11 in soft drink plant -

Refractometer IRM-11

Click here for more informationClick here for related articles and news

Sign up for Fluid Mixing E-Updates

Anderson-Negele, based in South Germany, is an international specialist for hygienic sensor technology in the food processing and pharmaceutical industries. The company philosophy “HYGIENIC BY DESIGN” embodies the fulfilment of customer requirements for process sensor and measuring technology in hygienic production environments. Product range:

At …

Source of Article